Lets start with the facts. A serger does not go backwards. This is significant because you cannot secure your seams with a back-tack, as with a sewing machine. Its a paradigm shift. Nothing too complicated, but it is there.

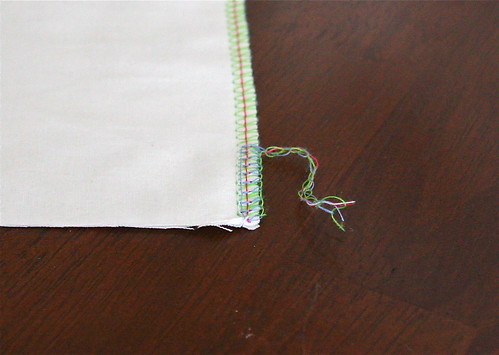

To be perfectly correct, a serger will go backwards, but its not designed to. The knife blade will cut off the stitches you just put on if you try to go backwards. Instead, always think of your serger only “serging forward”, never retreating. As the fabric comes out the other end of the presser foot, the stitching continues and you then clip the threads. The end of the threads is called a “serger tail”.

Public Service Announcement for the day: Do NOT clip the threads CLOSE to the fabric of the finished seam. This is a major no-no.

Lets look at what you can do to finish off your seams. There are several methods that can be used, but I only show my favorites. There is a method of using a special double eyed needle (your local sewing shop should have these). Its a larger needle with flattened ends and large eyes on both ends. One can run this through the loopers about an inch, coming out the end with the tail. Then loop the tail through the eye and pull back through. Notice that I like this method so much that I don’t even have a needle to show you how. Yep, I like it that much.

If you are running another seam across the previously sewn seam, then you don’t need to secure the tail, it will be secured by the next stitching.

My preferred way of doing things is right at the machine, as I am serging. It helps me stay in the groove not to have to get up and fiddle with anything else. Or it could be laziness, but I prefer to think of it as efficiency.

To start this lesson, we need a couple new vocabulary words. “Stitch Fingers” Peer under your raised presser foot where the needles go into the machine. You should see a piece that looks like a fork built into the bed of the machine. The needles go in-between the tines of this fork. This fork is the stitch fingers. Its what holds the fabric and enables the loopers to do their whole looping thing. We will re-visit this vocab word when we talk about rolled hems.

Next vocab word/phrase. “Lock the Knife” This means that we are going to turn off the knife. On this model its the little switch shown above. Some sergers have little dials on the front. Some you have to open the front of the machine and pull on the blade and swing it up out of the way. Now don’t get all excited thinking that you can now serge through the center of a piece of fabric because the machine is no longer cutting. The upper looper will destroy any of those dreams. Please discard them now before you ruin your project.

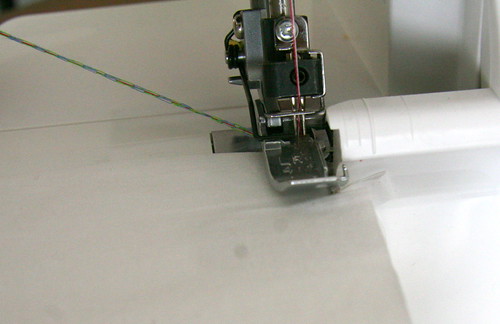

So, lets start with the beginning of the seam. Get the fabric in there and stop as soon as the needles reach the fabric. Also, make sure that you have some thread coming out the back already. One does not have to be houdini, its perfectly acceptable to use the hand-wheel to get where you need to be. The needles MUST be IN the fabric for this to work.

Lift up the presser foot. Then grasp the end of the thread tail and pull it back first to get it off the stitch fingers. Please don’t pretend that you are in the tug-o-war challenge in the iron man competition, just a gentle tug will do. Swing this tail to the left….and…..

Then swing it around the front of the needles. I like to put mine at a slight angle so that it will be cut off by the knife. Lower the presser foot. Serge on.

I’m sure you can make yours look better than this one. I like them a bit tighter. But this is acceptable.

Onto the other end of the seam.

For this method, you need to be just BARELY off the end of the fabric. You may use your hand-wheel again. And the needles need to be UP, this time. Raise the presser foot. LOCK the KNIFE!

Tug the fabric to the back gently to get it off the stitch fingers. Now we are going to flip it over, without moving anything. Pull the end towards you.

Flip it completely over, then settle it under the foot. Notice that the lower looper is now on top. Put the foot down and serge for about 1″. Stop.

We are now going to come off a seam in the middle. This is a very useful technique. Study this well. Some people will slowly pull the fabric off to the left. I think this isn’t ideal. For me, you get this section of “oooh I think we are going off…..yep, going off…..still going off….almost there…..just about….whew, we are off.” I think it looks sloppy. So I prefer to “tee-off”.

To “Tee-Off”, first you must stop where you want to come off. Raise the needles out of the fabric. Raise the presser foot. Make a 90 degree turn with the fabric. I call this making a “T”. With the presser foot UP, step on the gas pedal and come off the fabric. Nice clean, on purpose, no weird loops to deal with.

There ya go, the other end of the seam all secured. Oh wait, there is still a tail!

Clip off the tail close to the seam. Then dot some of this onto the loose ends. This is fray block and will prevent anything from unraveling. This tube will last you a long, long time. You may also use Fray Check. I prefer Fray Block because it isn’t scratchy when it dries.

There are some times when these methods won’t work. Sadly, you must have more than one trick in your bag. If nothing else works, pull the tail to one side of the serged seam and move over to your sewing machine. Do a quick zig-zag to secure the ends.

Comments on this entry are closed.

{ 16 comments }